| Parameter | Typical Value |

|---|---|

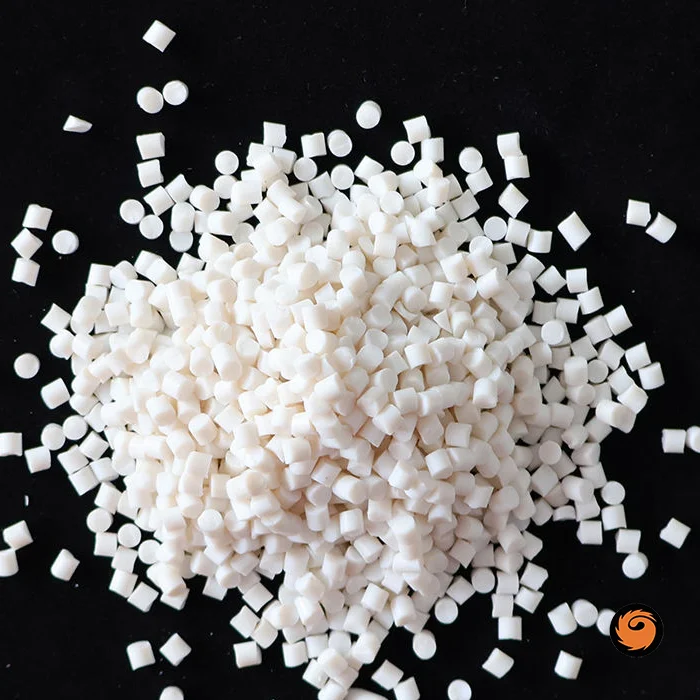

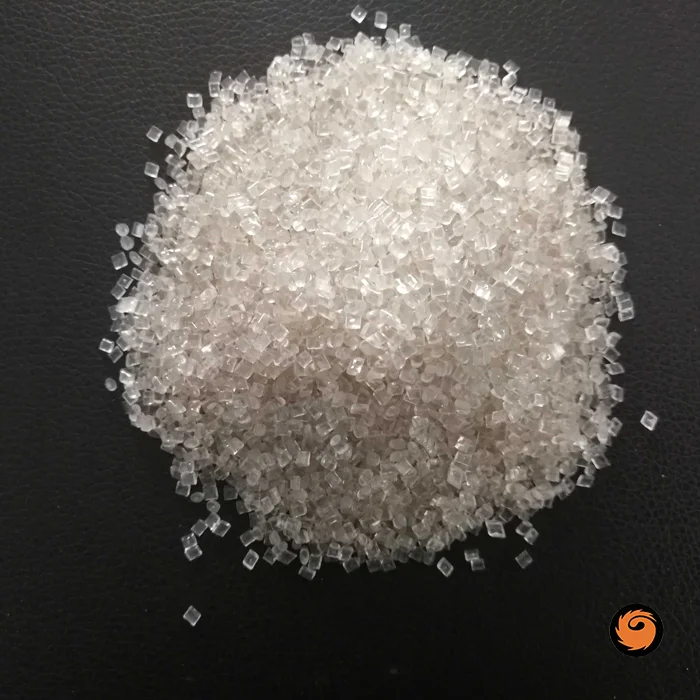

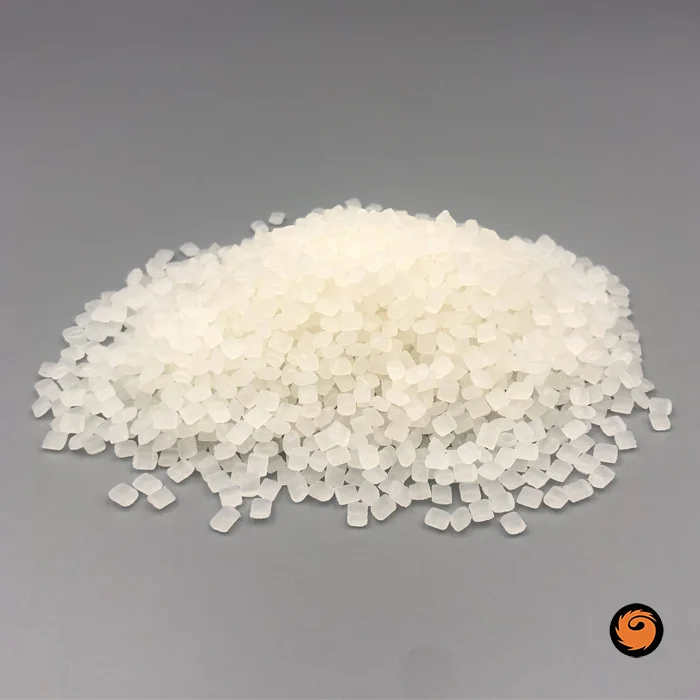

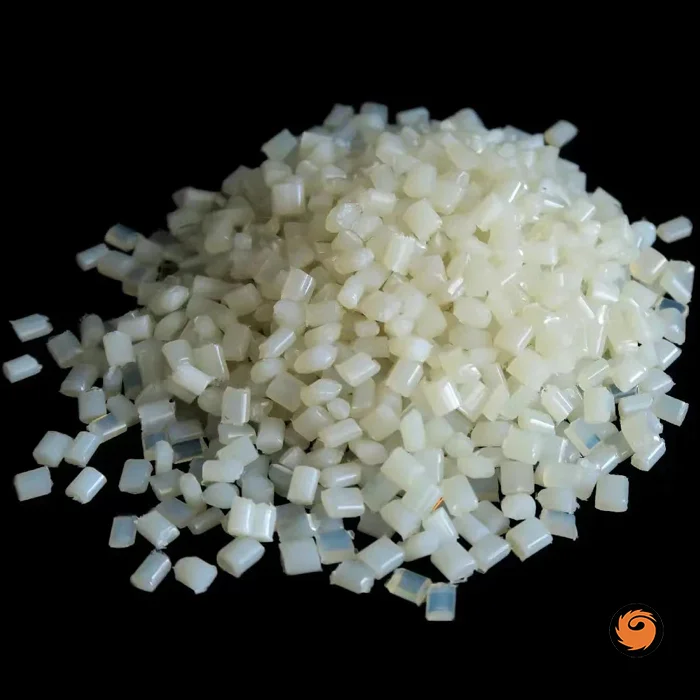

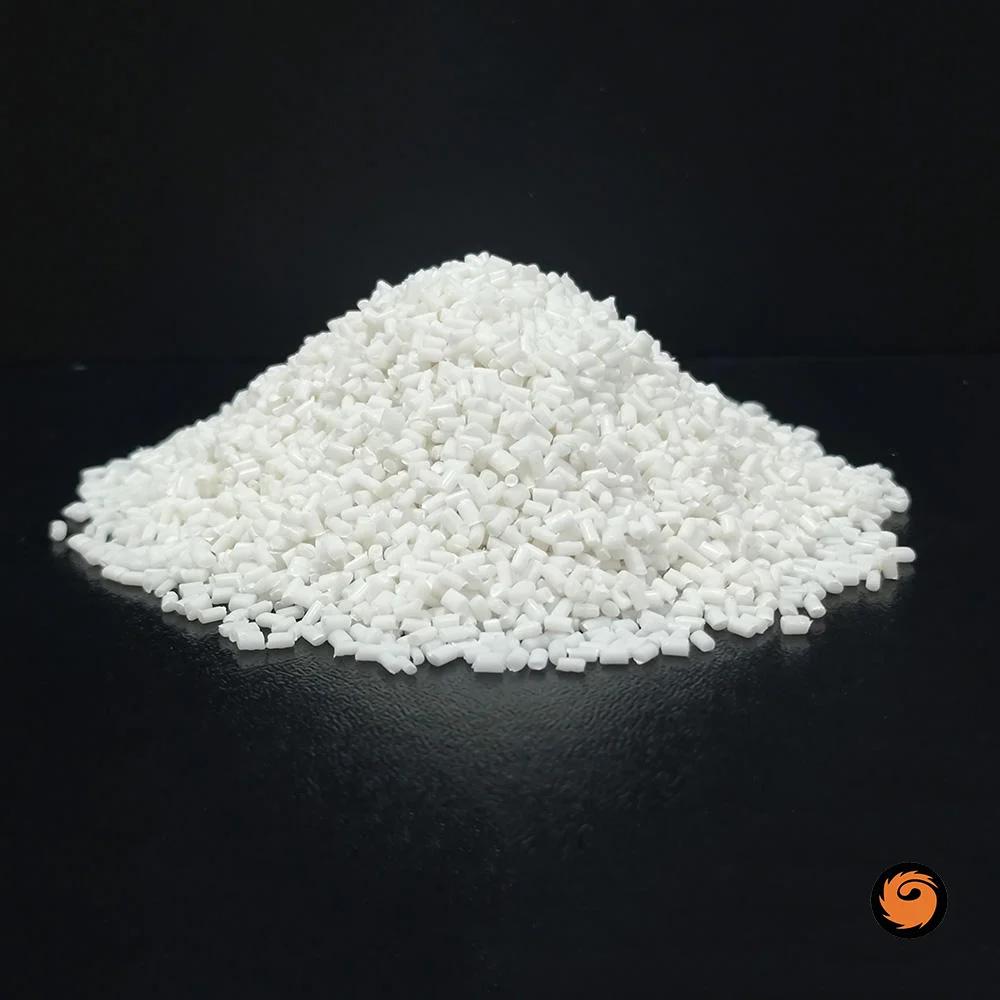

| Appearance | White or light gray granules |

| Carrier resin | PP / PE |

| Moisture absorption | High, suitable for humid environments |

| Recommended dosage | 4% |

| Processing temperature | 180–250°C |

| Compatibility | PE, PP, ABS, PS, PET, EVA |

| Function | Eliminates and reduces bubbles in molten plastic, improves product surface smoothness |

| Packaging | 25 kg per moisture-proof bag |

| Storage | Store in a cool, dry environment, away from direct sunlight |

| Delivery time | 7–15 days after order confirmation |

| Shelf life | 6–12 months (sealed and dry storage) |

Although plastic defoaming Masterbatch are of high quality and low price, they should pay attention to the occurrence of these doubts in use, and prevent them in time to prevent unnecessary troubles.

1. Prevent the plastic defoaming masterbatch from absorbing moisture before use.

2. It is better to use immediately once open it.

3. When using plastic defoaming masterbatch, do not heat and dry it together with damp plastic to prevent poor quality during processing.

4. Before using the plastic defoaming masterbatch, check whether the packaging is intact, and heat seal the unused masterbatch as soon as possible.

Applications

Ideal for use in:

- Film blowing – packaging and agricultural films

- Injection molding – containers, household items

- Extrusion molding – pipes, sheets, and profiles

- Blow molding – bottles and cosmetic packaging

It ensures bubble-free, smooth, and glossy plastic surfaces while enhancing production efficiency.