Technical Parameters

| Parameter | Typical Value / Range |

|---|---|

| Carrier Resin | PP / PE |

| Filler Type | CaCO₃ / Na₂SO₄ / Other Transparent Fillers |

| Filler Content | 10% – 40% |

| Dosage in Final Product | 4% – 10% |

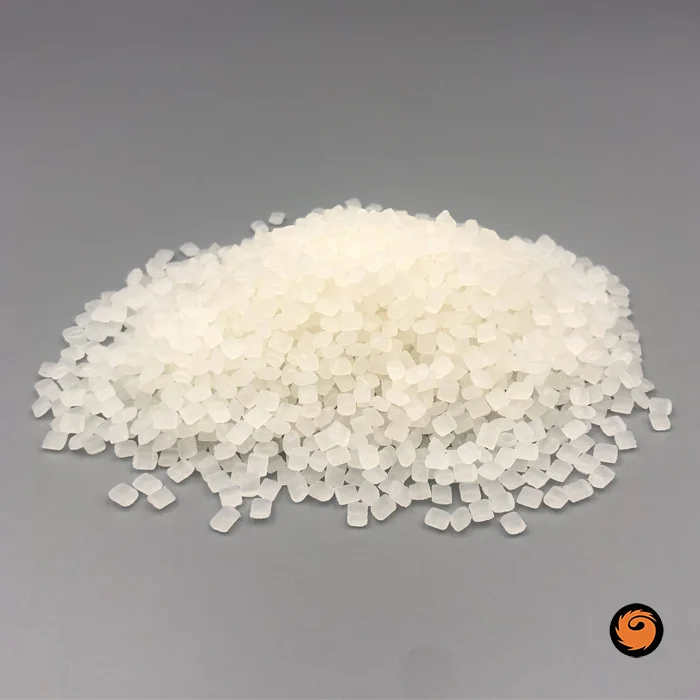

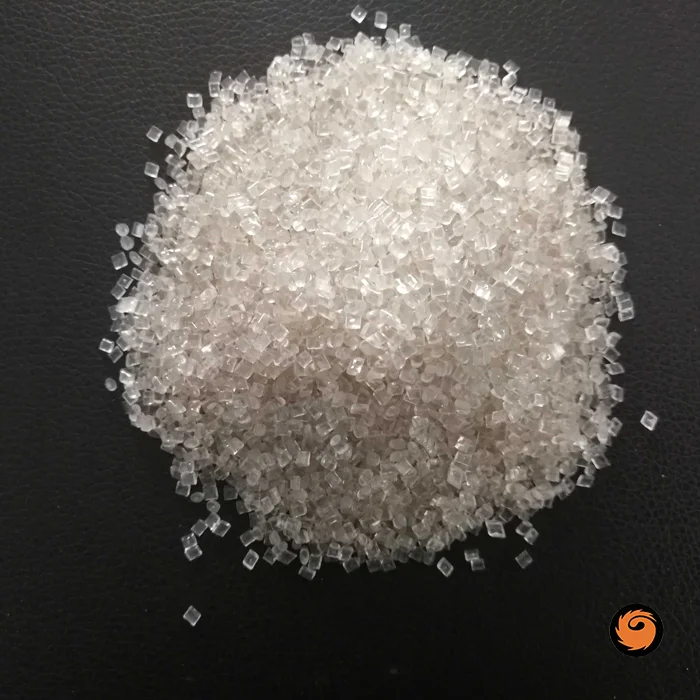

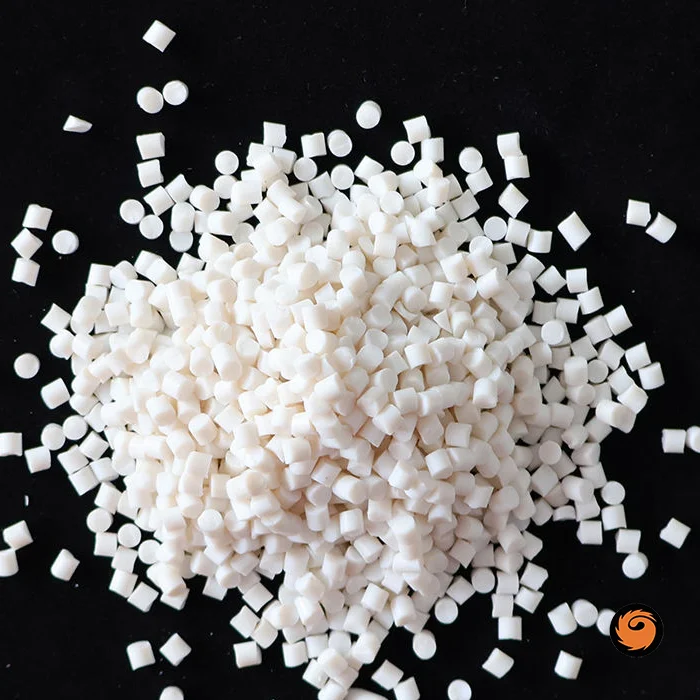

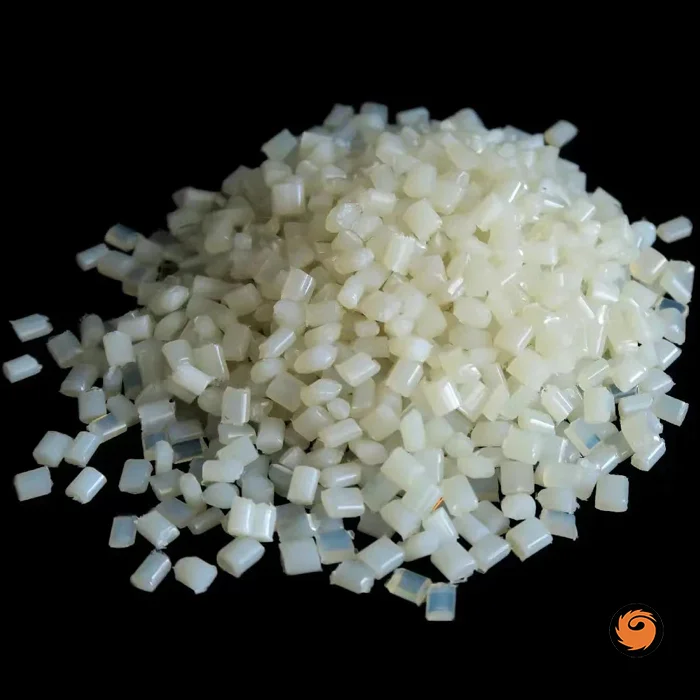

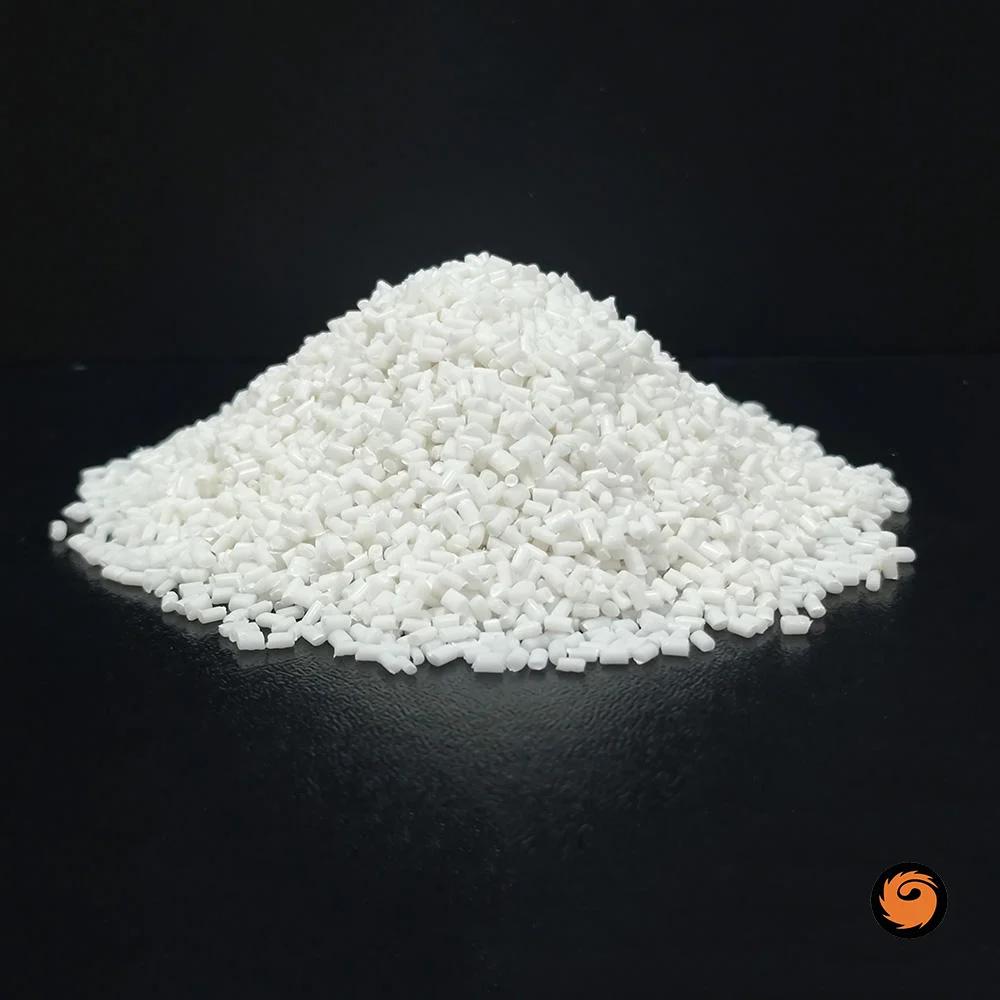

| Appearance | Transparent or translucent granules |

| Melt Flow Index (MFI) | 8 – 12 |

| Light Resistance | Grade 7 |

| Moisture Content | < 0.15% |

| Processing Temperature | 180 – 250 °C |

| Packaging Unit | 25 kg per bag |

Packaging & Delivery

- Packaging: 25 kg moisture-proof woven bags with PE inner liner.

- Delivery Time: 5–10 working days after order confirmation.

- Shipping Options: FOB, CIF, or customized according to client needs.

- Storage: Store in a cool, dry place away from sunlight and humidity.

After-Sales Service

- Technical Support: Professional guidance on dosage, blending ratio, and processing conditions.

- Sample Testing: Free samples for pre-production testing and verification.

- Quality Control: Every batch is rigorously inspected to ensure stable quality and performance.

- Responsive Service: Prompt assistance and solutions for any technical or product issues.

- Customized Solutions: Tailor-made formulations for different resins and transparency levels.

FAQs

Q1: What is a transparent filler masterbatch?

A transparent filler masterbatch is a compound of ultra-fine fillers and a compatible polymer carrier designed to lower cost while keeping plastic products clear and bright.

Q2: Which materials can it be used with?

It is suitable for PE, PP, PET, ABS, PS, and TPU, and works well in extrusion, injection molding, and film blowing.

Q3: How much should I add?

The recommended dosage is 4–10%, depending on the desired balance between transparency and cost reduction.

Q4: Will it affect optical or mechanical performance?

No significant impact when used correctly. The ultra-fine fillers and optimized carrier resin maintain optical clarity and mechanical strength.

Q5: Is it suitable for food-contact applications?

Yes, food-grade options are available and can meet relevant regulatory standards.

Q6: Can RongFeng customize the product?

Yes, RongFeng offers custom transparent filler masterbatch formulations to match your base resin, production process, and transparency requirements.